Struggling with a tricky plastic part design?

Not sure if your assembly method will hold up in production?

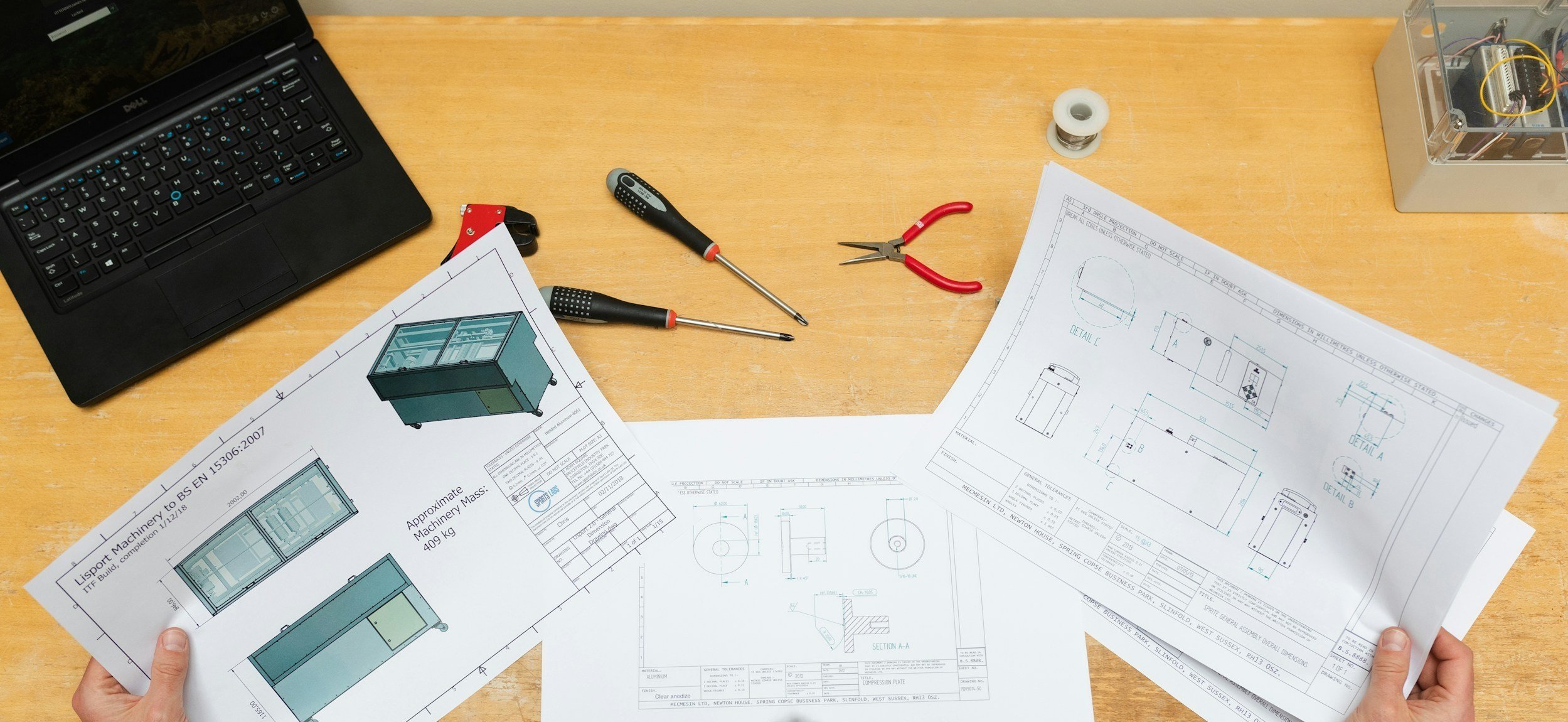

With over 30 years of hands-on mechanical engineering experience, I help you solve real-world design challenges by optimizing plastic parts, streamlining assembly, and turning good ideas into great products.

Plastic Part Design & Optimization Expertise in designing complex, high-performance plastic components for manufacturability, durability, and cost-efficiency. Specializing in design for injection molding, snap-fit features, living hinges, over molding, and tight tolerance parts.

Assembly Methods & Design for Assembly (DFA) Proven experience in designing parts and systems for efficient manual, semi-automated, and fully automated assembly. Consulting on bonding, ultrasonic welding, press-fit, mechanical fasteners, and other joining techniques specific to plastics.

Material Selection & Performance Engineering Assistance in choosing the right plastic materials based on mechanical performance, environmental conditions, cost, and compliance requirements (e.g., FDA, RoHS, REACH).

Prototyping & Product Development Support Guidance through early-stage prototyping to full-scale production, including CAD modeling, tolerance stack-up analysis, failure modes analysis, and iterative design improvements.

Manufacturing Interface & Supplier Support Acting as a technical liaison between design teams and molders, toolmakers, or assembly vendors to ensure seamless transition from concept to production.

Problem Solving & Design Reviews Conducting detailed design reviews and troubleshooting part failures, fit issues, or assembly inefficiencies to deliver practical, long-lasting solutions.